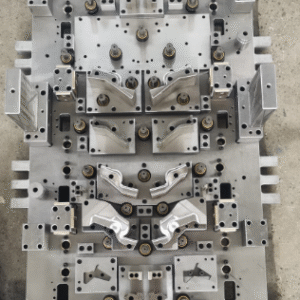

Automotive cold stamping parts are metal components manufactured using cold stamping technology. The core process involves a series of plastic deformation steps performed at room temperature, including blanking, forming, trimming, punching, and finishing, all carried out through specialized dies. The materials used typically include cold-rolled steel, high-strength steel, and aluminum alloys. This process results in high-precision, high-strength components with complex geometries. These part

s are widely used in body structures, safety components, powertrain systems, and interior/exterior trims, such as body longitudinal beams and battery trays. The image on the right showcases selected parts from the Changan project.

Uncategorized

Reviews

There are no reviews yet.